Pre-words: More and more people need the portable battery pack in their life, there are wide choices for it, but usually they may ignore or knew few for the big role in the battery pack, that's the BMS protection board. And this blog is to provide detail introduction of the BMS board. Here're 5 topics included.

- What are they ? BMS board/ PCM board

- Why does lithium ion battery need BMS board?

- How does BMS board work?

- What would happen if lithium ion battery is over-charged or over-discharged?

- Why it’s a must to use BMS?

1. What are they ? BMS board/ PCM board

PCM/PCB is called protection module or board. It’s the personal doctor of a lithium ion battery/LiFePo4 battery pack, It will always stand there to measure the battery voltage to prevent or avoid abnormal conditions such as battery over-discharge, over-charge, and over-temperature to hurt the cells.

Usually it’s used for lower voltage battery pack (<20 cells). It’s better to choose PCM/PCB with equilibrium function to keep each cell in balance and good service life.

While BMS board is an upgraded system of PCM. The full name is Battery Management System. It’s developed with many more functions. Generally, it’s used for higher voltage lithium battery pack, ( >20 cells) . It aims to monitor each cell’s performance to ensure the battery’s safer operation. Thus more complicated working than a PCM.

The battery management system is tightly integrated with the power battery of the electric vehicle. The sensor detects the battery voltage, current, and temperature in real time. It also performs leakage detection, thermal management, battery balance management, alarm reminder, and calculates the remaining capacity (SOC) , Discharge power, report battery deterioration degree (SOH) and remaining capacity (SOC) status, and also use algorithm to control the maximum output power according to the voltage, current and temperature of the battery to obtain the maximum mileage, and use the algorithm to control the charger for the best current Charging, real-time communication with the vehicle master controller, motor controller, energy control system, vehicle display system, etc. through the CAN bus interface.

The functions of BMS should include the basic battery protection function, battery balancing function, battery reserve energy measurement function and network communication function.

2. Why do lithium ion batteries need BMS?

The lithium battery management system can effectively carry out effective monitoring, protection, energy balance and fault alarm on the lithium battery pack, thereby improving the working efficiency and service life of the entire power battery pack. Lithium batteries are widely used in various precision equipment because of their many advantages such as high working voltage, small size, light weight, large energy density, no memory effect, no pollution, small self-discharge,and long cycle life. However, lithium batteries have serious defects. In summary, there are the following two aspects:

(1) Security

Lithium batteries have poor safety and sometimes have defects such as explosion. In particular, lithium batteries with lithium cobalt oxide as the positive electrode material cannot be discharged at a large current, and the safety is poor. In addition, almost all types of lithium batteries overcharge or over-discharge will cause irreversible damage to the battery cell. Lithium batteries are also extremely sensitive to temperature: if used under excessively high temperatures, they may cause electrolyte decomposition, combustion or even explosion; too low temperatures will cause the performance of lithium batteries to deteriorate significantly and affect the normal use of equipment.

Due to the limitation of battery manufacturing process, the internal resistance and capacity of each battery cell will be different. When multiple battery cells are used in series, the charge / discharge rate of each cell will be inconsistent, which leads to a low utilization rate of battery capacity. In view of this, the lithium battery usually needs a special protection system to monitor the health status of the battery in the actual use process, so as to manage the use process of the lithium battery.

(2) Maintainability

Lithium battery's capacity decay at low temperature and the unpredictable amount of electricity make the equipment less maintainable. Long-term online instruments require regular battery replacement, and the remote monitoring equipment work stations are scattered, and the distance between each station is long, so the battery replacement workload is huge and the cost is high.

In order to reduce the maintenance workload and maintenance costs, it is necessary for the lithium battery BMS management system to have an accurate charge state estimation function to accurately grasp the charge state of the battery, and more purposeful battery replacement work; at the same time, the battery management system is also required to have Low self-power consumption to reduce maintenance frequency and extend battery life. Therefore, for the remote monitoring instruments with long-term continuous power supply, the reasonable design of the lithium battery BMS management system has very important significance for the maintenance of the equipment.

3. What does BMS board work?

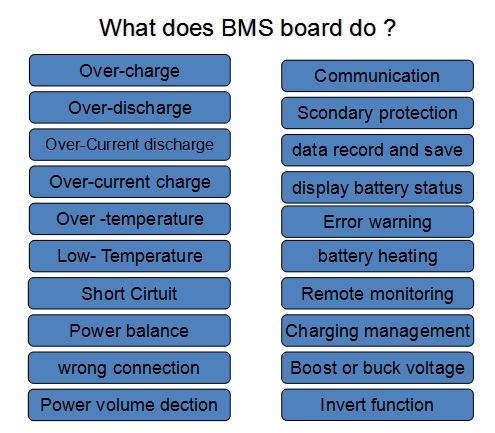

BMS is a complicated management system, here is a summary chart for its functions:

Here, we mainly introduce the following functions:

- Monitor battery status in real time.

By detecting the external characteristic parameters of the battery (such as voltage, current, temperature, etc.), and using appropriate algorithms to achieve the estimation and monitoring of the internal state of the battery (such as capacity and SOC, etc.), this is the basis and key to the effective operation of the battery management system;

As an important input part of the BMS control system, real-time monitoring of battery status parameters is particularly important.

The input parameters include: the voltage, temperature, equilibrium state of the single cell, and the temperature at the module jumper (BusBar temperature).

Output parameters include: battery capacity (SOC), battery life (SOH), etc.

The temperature sensor (NTC) is used to collect the cell temperature and BusBar temperature, and most of the voltage collection uses analog circuits.

The number of batteries is more than seven thousand in Tesla, BYD E6 also has hundreds of batteries. Therefore, it is impossible to collect the temperature of each cell, the cost is too high, and this is not necessarily necessary. Therefore, for a module, through thermodynamic simulation, the temperature pole positions are obtained, and the temperature envelopes of all the cells can be obtained by collecting these positions accordingly.

As above mentioned, the temperature of the battery cell does not need to be accurate to each battery cell, but the voltage of the battery cell is different.

As shown in the above figure, in the battery pack, theoretically, each cell should be tested consistently (voltage platform, discharge capacity, capacity, life, etc.) There are no two identical leaves in the world, so there are differences between the batteries.

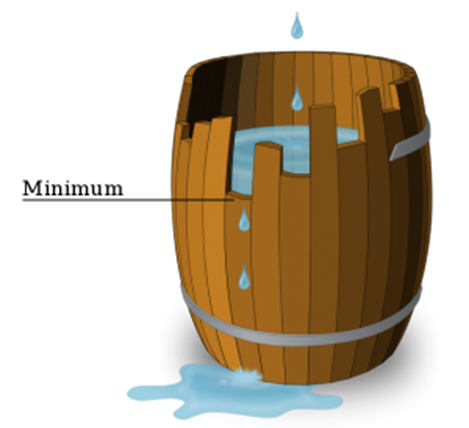

There are always good batteries and bad batteries in so many batteries. How to distinguish between good and bad? It can only be judged by the voltage of the battery cell, and the performance of the battery pack also just explains what is called the barrel effect.

Therefore, the voltage of each battery cell needs to be tested, otherwise the overall performance of the battery pack cannot be judged. Once a single cell is damaged, the entire battery pack is discarded. Therefore, the temperature collection of the cell voltage is more important, and most of them are currently implemented by AD sampling.

After collected the voltage and temperature of the cell, what is it used for? Need to judge the state of the battery is the core KPI to evaluate the battery state.

The battery state mainly includes the battery charge capacity(SOC: State of Charge ) and battery life (SOH: State of Heath)

These are the two most important parameters of the battery, one determines the discharge capacity, and one determines how long to live. Therefore, it is not difficult to judge that the core technology of BMS is here.

SOC:

The state of charge, also known as the remaining capacity, represents the ratio of the remaining capacity of the battery after a period of use or long-term storage, and its fully charged capacity, usually expressed as a percentage. Its value range is 0 ~ 1. When SOC = 0, it means that the battery is completely discharged; when SOC = 1, it means that the battery is fully charged.

To put it bluntly, the physical meaning of SOC is the current discharge capacity of the battery, just like the water in the bucket, how much water is there. Under normal circumstances, the vehicle will limit the use availability of the SOC. According to the test conditions of different batteries, choose 5% ~ 95%, that is, 90% use availability , or 2.5% ~ 98.5%, or 95%. But if the SOC estimation accuracy is around 3%, then the SOC use availability is at least 3% to 97%. Therefore, the estimation accuracy of SOC directly affects the available capacity of the battery.

SOH:

Battery capacity, health, performance status, that is, the percentage of the battery's full charge capacity relative to the rated capacity, the new factory battery is 100%, and the complete scrap is 0%.

Like SOC theory, vehicles will also restrict SOH. It is no problem that the new factory battery is 100%, but it depends on the conscience of the industry if it is completely scrapped. BYD claims that the lifetime warranty is not very reliable, because after the car's SOH reaches 80%, the battery life will be greatly reduced. For example, when SOH = 100%, NEDC can run 300Km, SOH = 80%, only run 200Km Too. Users are very uncomfortable, so there is a basis to ensure that the battery attenuation cannot be lower than 80% for 8 years.

Therefore, whether the two parameters of SOC and SOH directly determines the BMS quality.

- Perform thermal management, battery balance management, charge and discharge management, and fault alarm after obtaining the battery status correctly

Battery management, this must be the core part of BMS , it mainly includes: thermal management, battery balance management, charge and discharge management, and fault alarm.

Completed the collection of battery parameters, and correctly estimate the battery SOC and SOH is the basis for battery management.

Thermal management, handle the temperature of the battery, and control the battery temperature within the appropriate range. why? Because the battery is delicate, there is less discharge when the temperature is low, too high temperature is easy to runaway, and high temperature and low temperature discharge will also be dangerous. Therefore, by using a reasonable algorithm and logic to control the battery temperature within the most suitable range of the battery cell, the battery can be discharged happy and live a long time.

Battery balance management, handle the voltage of the battery cell, keep everyone the same. why? Because everyone is born unequal, in a legal society, equality is the core and cannot cause "polarization." Some batteries are of good quality and have a lot of discharge. Some batteries are of poor quality and discharge fast, so let a good battery discharge faster. Everyone is equal, and they are twisted together to charge and discharge, and the battery pack can live longer.

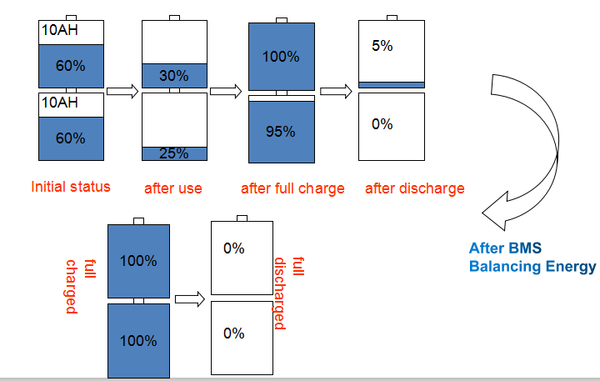

BMS’s energy balance function works: it is to make up for the differences between individual cells to do some active or passive charge or discharge management to ensure battery consistency and extend battery life.

Here is chart to show the BMS energy balancing function:

Charge and discharge management, interact with slow charge and fast charge piles, design charge and discharge current and charge and discharge strategy. Is the battery not a passive original? Yes, the battery is passive, but the battery itself can be actively reported to an external controller, and they can actively control the battery's charge and discharge current.

Fault alarm, diagnose the battery management situation, and carry out corresponding fault handling. This is easy to understand. Just like a country has a government, a disciplinary inspection commission, and a supervisory commission, it cannot arbitrarily dictate. There is something wrong with the control system, rely on the fault alarm system to find problems in time and protect the battery.

-

Establish a communication bus to realize data exchange with the display system, vehicle controller and charger.

In short: collecting battery information, calculating battery status parameters, and communicating with external controllers.

Just mentioned the charge and discharge control, you need to interact with the controller such as slow charger, slow charging pile, fast charging pile, how to interact? Data exchange through communication protocol.

The battery is a passive device. It needs to report its own situation in real time to protect itself. Of course, when it is absolutely necessary, the self-cutting relay is powered off.

There are not many controllers that interact with BMS, mainly vehicle controllers, slow charge controllers, fast charge piles, DCDC, meters, gateways, motors, etc. If it is a distributed BMS system, it also needs to interact with the CMU.

In summary, the workflow of the BMS control system is to collect the voltage, temperature and other signals of the cell and pass it to the control system to estimate the battery status (SOC, SOH), etc., for the control function of the BMS. Control functions mainly include fault alarm, thermal management, balance management, charge and discharge management, etc.

4. What would happen if battery is over-charged or over-discharged?

Here is some questions for user’s concern:

- Under what circumstances can the battery be overcharged?

- The charger voltage is higher than the standard voltage

- Multiple strings of cells have poor consistency. A cell full charged voltage tolerance should be in 0.002-0.005V range

- What will happen if the lithium battery overcharged?

- The battery pack swells

- Circuit slightly short, big power consumption

- Shorten the life of battery pack

- Leakage

- Fire

- Explosion

- Under what circumstances may the battery be over-discharged?

- The loading has no low-voltage shutdown function

- Multiple strings of cells have poor consistency. A cell full charged voltage tolerance should be in 0.002-0.005V range

- What will happen if the lithium battery over-discharged?

- Capacity decreased

- Increased internal resistance

- Shortened life,

- Battery pack swell

- Leakage

- Scrapped (voltage close to 0V)

- Under what circumstances the battery may discharge over-current

- The loadingis larger than the supporting loading

- The loading is damaged

In summary: The actual working current is much larger than the normal working current of PCM, but less than the over-current protection current

- Under what circumstances may the battery short circuit occur?

- The positive and negative poles of the output accidentally touched the metal

- The loading short circuit

- The charger output short circuit

Reminds: it Usually refers to the short circuit protection of the discharge port, whether the charging port has short circuit protection

5. Why it’s a must to use BMS?

There are safety issues from the generation of power lithium batteries to the end of life, even if they are fully compliant with international safety standards at the factory, they will evolve from a safe state to an unsafe state during use, and the performance of good-quality single cells gradually declines to achieve Life-span, single-cell batteries with poor quality will experience various abnormal deterioration and degradation during use, and enter the unsafe state of concern. This is a process of gradual accumulation.

Lithium battery BMS management system is not as optional as some battery manufacturers say, but it must be there, and it must be applied throughout the battery pack. Lithium battery management systems have been studied at home and abroad, and they have been applied in many fields. They have been able to meet the needs of some markets. The application of lithium power batteries has put forward higher requirements for battery management systems to ensure the safety of power battery packs. , Is the primary task of lithium battery management system.

As a powerful guarantee for the safe use of batteries, BMS keeps the batteries in a safe and controllable charge and discharge process at all times, greatly improving the cycle life of the battery in the actual use process. In the rapid development of new energy vehicles, BMS as a core technology plays an important role.

Leave a comment